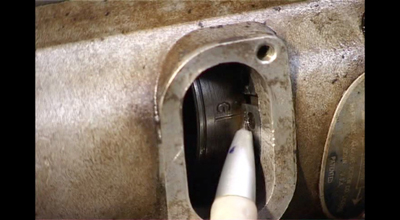

The engine block, connected below the cylinder, contains the crankshaft, connecting rod and piston. The head of a cylinder contains the system’s valves, camshafts, valve return springs, valve buckets and injectors.

Thermal energy comes from the combusted air-fuel mixture inside the cylinder. The created power moves an engine’s pistons, therefore, moving the crankshaft, then the marine unit itself. In an internal combustion engine, thermal energy transfers into mechanical energy. You may not understand everything that occurs within the system, but if you have an idea of how an internal combustion engine operates, you can make comprehensive timing injection adjustments. The internal components of a marine engine are complex and rely on precise movements to deliver efficient and reliable power.

In this guide, we’ll discuss how the process works, the benefits of making modifications to your Cummins engines or Detroit Diesel engines, and how to carry out adjustments on your own. Whether you’re looking for a boost in power or your engine is a bit older than you’d like to admit, adjusting the injection timing can affect the entire system. You may have heard of injection timing before, but what is it, and how does it relate to your marine engine? Do you even need to bother if your motor runs just fine?

0 kommentar(er)

0 kommentar(er)